A Quick Guide to Choosing the Correct Chiller

Heat is a common by-product of today's manufacturing machines, which include the advanced automation technology required for high-speed operation and high precision. Components such as spindle motors, variable frequency drives, lasers and X-ray sources all require cooling to operate properly and reliably - often in very harsh manufacturing environments.

As manufacturing space is at a premium and machine packages become smaller and smaller, liquid cooling has become the most efficient and cost-effective method of removing process heat. Particularly suited to hot, dirty environments, liquid cooling provides a way to remove heat from the machine without contributing additional heat back into the environment.

A quick guide to choosing the right chiller.

As every industrial environment is different, a 6-step guide to help you choose the right chiller for your application:

Water Cooled Screw Chiller

Step 1: Determine the thermal load

It is important to determine the thermal load of your application to ensure that the chosen chiller is large enough for the intended application. There are a number of ways to determine the thermal load (in BTU's) but understanding the process is essential to calculating an accurate thermal load.

Step 2: Determine coolant type, temperature and flow rate

When the heat load is known, the next step is to determine the coolant, its target temperature and the flow rate that the cooler must provide for the process. This depends on the method of heat transfer from the process to the coolant and the type of coolant used. Water, for example, has different properties to oil.

Step 3: Determine the installation environment

In what environment is the chiller to be installed? For example, indoor applications may encounter hot and dirty environments, while outdoor installations may encounter cold and hot environments. This can affect the size of the chiller and require accessories such as air filters, oil tank heaters etc.

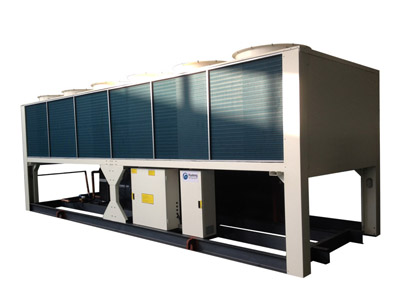

Air Cooled Screw Chiller

Step 4: Using chiller performance curves

Now use the available chiller performance curves to select a chiller model that meets or exceeds the required capacity based on the chilled water supply temperature and the maximum expected ambient air temperature. Application safety margins associated with available rack sizes should be considered to maximise the value of chiller selection. Find all Brannenberg chiller performance curves in the Thermal Management catalogue.

Step 5: Check pump performance curves

Check the available pump performance curves to ensure that the pump is able to deliver sufficient pressure at the design flow rate to meet the application. Some liquid cooling systems have smaller coolant flow paths or longer distances, so pressure losses may be higher than average.

Step 6: Final selection

Finally, consider the remaining application requirements such as power characteristics, control options, footprint, list of mechanisms, colours, etc. that have been met by the selected Standard Brannenberg chiller. Choosing a standard chiller will give you greater reliability, easier access to universal spare parts service and global support.

If you are looking for high quality best chiller for sale, welcome to contact us for detailed information!

评论

发表评论